Solid rivets can be used in many applications. Setting the rivet is achieved by passing the rivet through the material to be fixed and then either deforming the end of the shank or fitting a non return washer such as a "starlock". Deformation can be achieved crudely by hammering or in a more controlled fashion either by using a press or spin riveting.

Solid rivets can be used in many applications. Setting the rivet is achieved by passing the rivet through the material to be fixed and then either deforming the end of the shank or fitting a non return washer such as a "starlock". Deformation can be achieved crudely by hammering or in a more controlled fashion either by using a press or spin riveting.

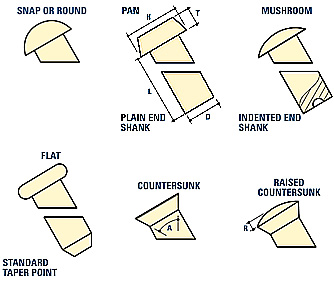

Head Forms

Shank Forms

BS641

| Head Type | Table No | H | T | A |

| Snap | 1 | 1.75D | 0.75D | |

Pan | 2 | 1.60D | 0.70D | |

Mushroom | 3 | 2.25D | 0.50D | |

Flat | 4 | 2.0D | 0.25D | |

60° Countersunk | 5 | 1.75D | 0.65D | 60° CSK |

90° Countersunk | 6 | 2.0D | 0.5D | 90° CSK |

120° Countersunk | 7 | 2.0D | 0.29D | 120° CSK |

140° Countersunk | 8 | 2.75D | | |

CSK Reaper | 9 | 1.65D | 0.32D | |

Snap Reaper | 10 | 1.65D | 0.60D | |

Table C

BS4620

Head Type | Table No | H | T | A |

Snap | 1 | 1.75D | 0.60D | |

Universal | 3 | 2.0D | 0.40D | |

Flat | 5 | 2.0D | 0.25D | |

Countersunk | 6 | 2.0D | 0.50D | 90° CSK |

Table D